Shell and Tube Heat Exchanger Design (S&THex). Very easy to use and user friendly.

S&THex is a software tool that is made to demonstrate the chemical design and rating calculations of Shell & Tube Heat Exchangers. The software unlike other tools, ensures that the calculations are performed step by step to help in understanding the calculations.

Software Features

- Step by step design and rating calculations.

- Support S.I Units and English (U.S) Units of measurement

- Rating and Design Modes

- Units converter containing 23 measurements and 200 units conversions

- Save, Load and generate result in different formats

- Compare unlimited cases in data grid table. This feature has now been automated to allow case study scenarios for optimisation. User can select the optimisation parameters from available one and run a multi case study

- Add your own Nusselt number correlation to be used in the design mode or rating mode. The correlation can be added in the following format;

Nusselt number = C * [Reynolds number ^ a] * [Prandtl number ^ b] * [Viscosity term ^ c]

Where; C, a, b and c are input variable defined by the user. the user can also choose to omit the viscosity term if needed.

Results:

• Generate Results and export it to Shell & Tube Engineering Data sheet that can be also saved as a .pdf document.

• Export results to Microsoft excel generated data sheet for editing.

• Export Results summary to .csv file format that can be opened in Microsoft Excel• Export Results summary to .rtf file format that can be opened in Microsoft Word

• Print preview / print Results summary

Calculations:

The software performs many thermal analysis calculations and some mechanical calculations, as it is too lengthy to list all the calculations, a summary has been listed below.

- Unknown Flow rate on either shell or tube side

- Unknown temperature on shell side or tube side

- Unknown exit temperatures on both sides

- Duty, Area, Shell and Tube velocities

- Number of Baffles and Baffle spacing, Number of tubes, Scale resistance (dirt factor)

- Overall heat transfer coefficient for both Clean, Fouled and Required conditions

- Select from different correlations to calculate shell or tube heat transfer coefficient

- Shell/Tube side Reynolds & Nusselt numbers

- Pressure Drops

- Recommended minimum shell thickness, minimum recommended number & diameter of rods.

- Calculate Shell/Nozzle/Channel/Head/Tube sheet Thickness.

- Number of transfer units, Effectiveness, Thermal capacity ratio

- Pumping power / Inlet and Exit Nozzles pressure losses / Scale resistance Calculators

- Ability to import properties to Shell/Tube sides form Microsoft Excel very useful if you want to import your own physical properties Included

Download

Click here to download the demo version of the product. Please also note that the demo version of this software will only operate with set examples which are restricted in our demo version. The full version of this product does not have any restrictions.

We don’t offer a fully working demo version.

To check the latest update history of this software against the version you have to see what was added please click here

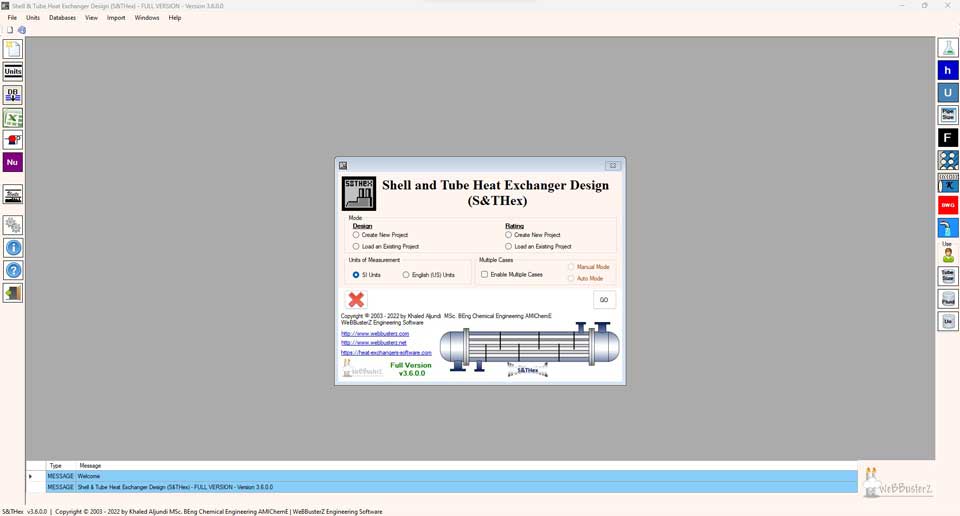

Screen Shots

To see more screen shots please follow the links on our screen shots page

To view a demonstration video on YouTube please see below:

Interface video – Click here

Design Mode Example 1 – Click here

Design Mode Example 2 – Click here

Rating mode example 1 – Click here

Rating mode example 2 – Click here

Importing physical property file – Click here

Temperature calculation video clip – click here

Case study automation – Click here

More Features

Databases:

- Estimate the Physical properties of pure components for more than 1450 components; the database has the ability to estimate Thermal Conductivity, Density, Heat Capacity and Viscosity. The database also included critical properties, boiling and melting points and come as a standalone interface but easily integrated with the software.

• Estimate mixture properties. (ALL ESTIMATION METHODS CURRENTLY SUPPORT LIQUIDS ONLY) - Ability to add your own properties in the additional user databases.

- Backup and restore user databases

- Tube counts. Including kern tube counts

- Fouling factors and Overall heat transfer coefficients included.

- Material thermal conductivities

- Standard pipe sizes and Birmingham Wire Gage Scale

- Water and steam properties

Chart Plotting Feature

- Heat duty versus Temperature

- Number of Tube passes Versus Tube side Pressure Drop

- Temperature profile (inlet and outlet temperature profile for both shell and tube sides)

Below are a tabulated list of calculations, this list below isn’t conclusive and other calculations are also performed based on conditions.

| Calculation | Rating mode / Rate an existing design | Design mode / Design a new exchanger |

|---|---|---|

| Unknown Inlet temperature on either shell or tube / hot or cold sides | – | Calculate |

| Unknown Outlet temperature on either shell or tube / hot or cold sides | – | Calculate |

| Unknown two Temperatures one shell side and another tube sides | – | Calculate |

| Unknown Flow rate on either sides | – | Calculate Mass flow or Volumetric flow based on selection |

| Shell Diameter | – | Calculate or Enter |

| Shell Thickness | – | Calculate or Enter |

| Minimum Recommended Shell Thickness | – | Calculate |

| Baffle Diameter | – | Calculate |

| Baffle minimum recommended thickness | – | Calculate |

| Bundle to Shell clearance | – | Calculate or Enter |

| Baffle to Shell diametral clearance | – | Calculate or Enter |

| Number of Baffles | – | Calculate |

| Baffle Spacing | – | Calculate or Enter |

| Prandtl numbers, Reynolds numbers | Calculate | Calculate |

| Unknown Outlet temperatures on both sides | Calculate | Calculate |

| Heat Duty | Required input but can Calculate | Calculate or Enter if Exit temperatures are unknown |

| Heat Transfer Area | Required input but can Calculate | Calculate |

| Log Mean Temperature Difference (Co-Current and Counter Current Flows) | Calculate | Calculate |

| Tube wall temperature | – | Calculate |

| Velocities (Shell and Tube sides) | Calculate | Calculate |

| Volumetric Flow rate | Calculate | Calculate |

| Number of tubes | Required input | Calculate |

| Tube to tube Clearance | Calculate | Calculate |

| Number of tubes per pass | Calculate | Calculate |

| Tube cross sectional | Calculate | Calculate |

| Area per pass | Calculate | Calculate |

| Number of transfer units | Calculate | Calculate |

| Effectiveness | Calculate | Calculate |

| Thermal Capacity Ratio | Calculate | Calculate |

| Nusselt Number | Calculate based on correlation selection or Enter | Calculate based on correlation selection or Enter |

| Heat Transfer Coefficients on both sides | Calculate or Enter | Calculate or Enter |

| Scale Resistance (Dirt Factor) | Calculate | Calculate |

| Pressure Drops: Shell/Tube/Nozzles | Calculate | Calculate |

| Overall Heat Transfer Coefficients (Clean and Design) | Calculate | Calculate |

| Overall Heat Transfer Coefficients (Required) | – | Calculate |

| Over design and Over Surface | – | Calculate |

| Tube hole diameter – Baffles | – | Calculate |

| Recommended Tie Rod diameter | – | Calculate |

| Minimum number of Tie Rods | – | Calculate |

| Head Thickness | – | Calculate |

| Nozzles Thickness | – | Calculate |

| Tube Sheet Thickness | – | Calculate |

| Tube Channel Thickness | – | Calculate |

System Requirements

Operating System: Windows 7, Windows 8.1, Windows 10, Window 11

Microsoft.net framework 4.8 installed